Enter an other dimension!

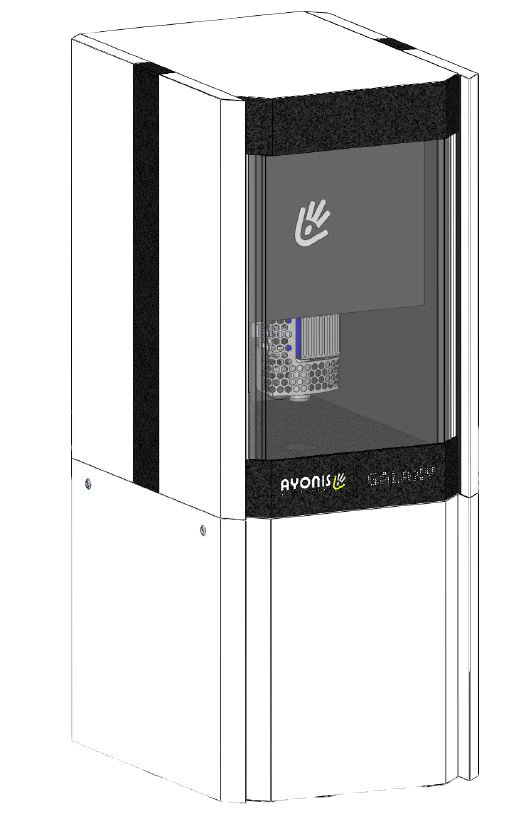

Galaxy is the latest innovation of the metrology machines developed by Ayonis.

This is the result of more than thirty years of experience in contactless metrology.

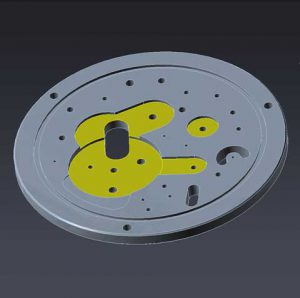

These machines are unique simultaneously thanks to their scanning technology, the double-sided configuration (model DS331) and their capabilities. They offer new performances both in inspection time and accuracy.

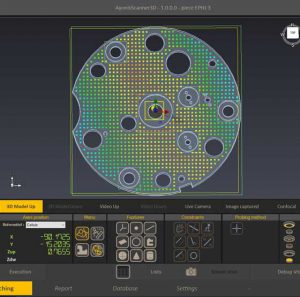

Designed as production machines and equipped with a new software platform “Galaxy Suite” that meets the new requirements of 3D metrology, they perfectly fit the latest generation of production environments.

Enter the era of metrology 4.0!

GALAXY DS 331

GALAXY DS 331 GALAXY OS 111

GALAXY OS 111 GALAXY CF 111

GALAXY CF 111 GALAXY OS 442

GALAXY OS 442 GALAXY OS 211

GALAXY OS 211